Titans Drop Packers

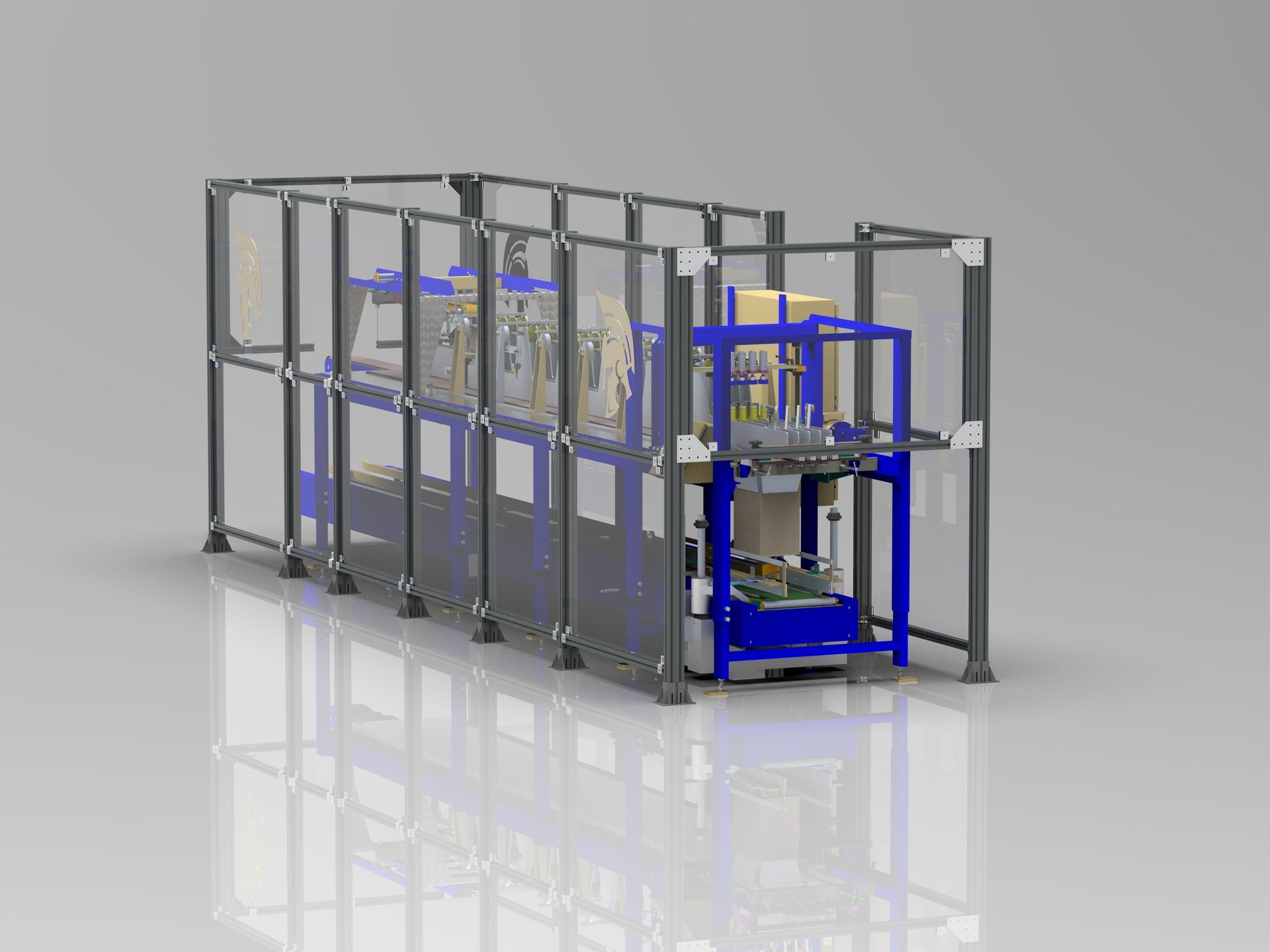

A well built drop packer can be the most important packaging machine on your line. Titans drop packers are highly customizable and reliable. Add a case erector and case sealer for a complete end of line solution. All Titans packaging machinery and conveyors are manufactured in the United States.

Titans Hyperion TDP20 Drop Packer

- Speeds up to 20 cases per minute

- Belt-Type Case Conveyor

- Allen-Bradley Controls/Station

- Titans Interchangeable Change Parts

- 1 Year Warranty

The Best Drop Packer for Flexible, High-Speed Case Packing

Titans Packaging Hyperion TDP20

When your production requires a robust, flexible, and easy-to-operate drop packer, the Titans Hyperion TDP20 sets the standard. Designed for beverage, food, and consumer goods packers who need compact automation that performs under continuous operation, the TDP20 delivers dependable throughput (up to 20 cycles per minute) with industry-leading ease of use and uptime.

Features

- Speeds up to 20 cycles per minute — ideal for entry to mid-level automation and scalable production lines.

- Ultimate flexibility — runs multiple pack patterns (4-pack, 6-pack, 8-pack, 12-pack, 15 pack, 18 pack, 24 pack and 30 packs - custom formats) and adapts quickly to new products.

- Tool-less changeover — drastically reduce downtime: change guides, lanes, and format parts without tools or lengthy adjustments.

- Lane divider upgrade available — convert wide lanes into multiple narrow lanes for mixed SKUs or smaller formats.

- Durable design for 24/7 operation — heavy-duty frame, industrial bearings, sealed motors and easy maintenance access points for continuous production.

- 1 year parts warranty — confidence and protection on critical components.

- Operator-friendly HMI — simple recipe selection, diagnostics, and quick troubleshooting.

- Compact footprint — maximizes floor space; integrates easily with infeed conveyors, cartoners, and case packers.

Common applications

- Beverage (cans, slim cans, bottles)

- Bottled products (glass or PET) with gentle handling requirements

- Food trays and thermoformed goods

- Personal care and household goods

- Specialty products with irregular shapes (consult for feasibility)

- F style jugs

Features In Detail

Performance & handling

- Throughput: Up to 20 cycles per minute (configurable by product, pack pattern, and line integration).

- Gentle handling: Controlled drop heights and product guides minimize product impact and damage.

- Multiple pack patterns: Standard and custom patterns supported. Recipe recall via HMI enables fast swaps between formats.

Changeover & flexibility

- Tool-less changeover for the majority of format parts — reduces labor, shortens changeover time, and supports just-in-time production schedules.

- Quick-release guide rails and pucks make transitions fast and repeatable.

- Lane divider option allows splitting one infeed into 2–4 lanes (depending on product) for mixed packs or higher throughput across smaller SKUs.

Build quality & uptime

- Industrial construction: Powder-coated steel frame, stainless contact points where needed, and IP-rated electrical enclosure.

- 24/7 ready: Designed with redundancy in wear parts and accessible maintenance zones for rapid servicing.

- Safety & standards: Machine guarding, E-stop, and interlocks to meet global safety expectations.

Controls & integration

- Standard PLC & HMI with recipe management, fault logging, and remote diagnostics ready.

- Communications: EtherNet/IP, Profinet, Modbus TCP — integrates with central line controls and industry SCADA systems.

- Sensors & vision: Optional vision detection for product verification and reject handling.

ROI & production impact — what to expect

The Hyperion TDP20 is designed to reduce manual labor, increase line consistency, and cut packaging changeover time. Typical benefits for a growing production line:

- Labor reduction: Replace manual packing stations or semi-manual setups to reduce labor hours per shift.

- Downtime reduction: Tool-less changeover and modular parts shorten downtime between SKUs.

- Quality consistency: Fewer packing errors, reduced product damage, better first-pass yield.

- Payback: Many operations realize payback within 12–36 months depending on labor cost, uptime gains, and throughput improvements. Titans offers a line-level ROI analysis during quoting.

Upgrades & Customization

Customize the TDP20 to match your operation:

- Lane divider upgrade — create narrower lanes or multiple parallel packing lanes for mixed SKU production.

- Stainless package — full stainless contact surfaces for washdown or hygienic environments.

- Integrations — automatic infeed, lifters, outfeed conveyors, case packers, and palletizers.

- Special tooling — custom format parts for unique product geometries.

Installation, Training & Support

- Turnkey installation — optional on-site installation and commissioning by certified Titans technicians.

- Operator & maintenance training — on-site or remote sessions to speed operator competence.

- Spare parts & field service — local parts stocking, replacement kits, and remote troubleshooting available.

- 1 year parts warranty included — optional extended warranty and service contracts available.

Frequently Asked Questions (FAQ)

What is a drop packer?

A drop packer places products into cartons or trays by allowing controlled drops into a formed pack cavity. It’s ideal for high-speed, gentle placement and often has a smaller footprint than continuous motion cartoners.

How does a drop packer differ from other packers?

Compared to infeed push or vertical insertion systems, drop packers are simpler mechanically and excel with consistent infeed and multi-pack formats.

How long does a changeover take?

With tool-less changeover, most standard format swaps can be completed in minutes rather than hours. Exact times vary by pack pattern and operator experience.

Can the TDP20 handle different can and bottle sizes?

Yes. The Hyperion TDP20 supports a range of sizes through quick change format parts and adjustable guides. For very wide size ranges a lane divider or special tooling may be recommended.

Is the TDP20 suitable for 24/7 operation?

Absolutely. The machine is engineered for continuous duty with heavy-duty components, simplified maintenance access, and replacement part strategies to minimize downtime

What warranty is included?

The Hyperion TDP20 includes a 1 year parts warranty. Extended warranties and preventive maintenance contracts are available.

Get a Quote / Contact Titans Packaging

Ready to upgrade to a reliable drop packer that balances speed, flexibility, and durability? Contact Titans Packaging for:

- A free line evaluation and speed validation for your SKUs

- A formal quote, layout drawing, and ROI analysis

- Details on delivery times, installation, and training

Call: (513) 501-7240 | Email: nick@titanspackaging.com

Or click Request a Quote to upload product specs, photos, and target throughput and a Titans engineer will respond.

Need a complete custom End of Line Packaging Solution?

Titans Packaging can provide a complete end of line packaging solution to meet your needs! Request a quote today.